DB-HORSEPOWER-GFNL Industrial Fiberglass Cooling Tower

Product: Square counter current cooling

Tel:+86 13961837633

E-mal:464788795@qq.com

Add:A31, No. 48-11 Renmin West Road, Hudai Town, Binhu District, Wuxi, Jiangsu Province, China

E-mal:464788795@qq.com

Add:A31, No. 48-11 Renmin West Road, Hudai Town, Binhu District, Wuxi, Jiangsu Province, China

Made in china -

Jiangsu Century Hualeng Industrial Development Co., LTD

Focus on cooling tower: research and development, customization, production, service!

Manufacturer contact number: +86-13961837633 (China wechat account) Mr.Hu

Manufacturer contact email: 464788795@qq.com

Contact address: No.17, South Yingbin Road, Dongting Street, Xishan District, Wuxi City, Jiangsu Province

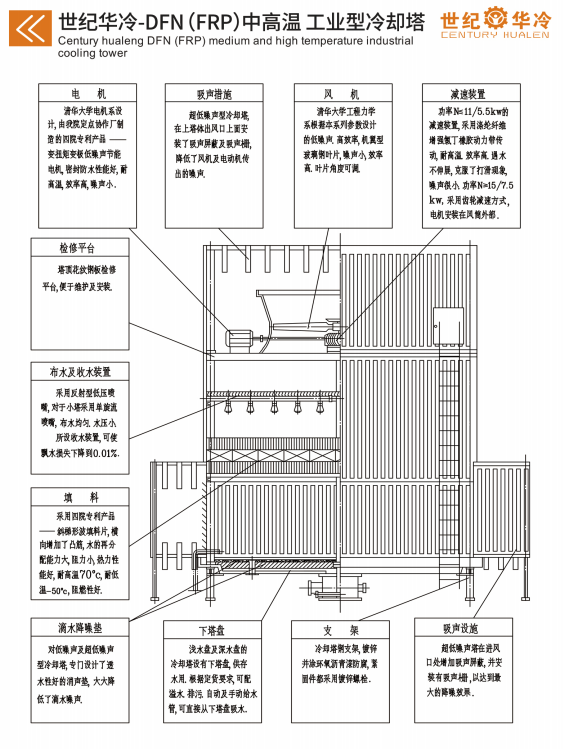

Overview of FHL-H FRP open cooling tower series

Since 1971, the Fiberglass Engineering Institute of the Fourth Design Research Institute of China's Ministry of Machinery Industry has been researching and designing cooling towers. The various models of cooling towers it has designed are widely used across the country and in various industries. The Fourth Design Research Institute is the only Class A design institute in China with a dedicated research institution for cooling towers. It is the lead editor of China's 'Glass Fiber Reinforced Plastic Cooling Tower' standard and the primary compiler of the second part, 'Large Glass Fiber Reinforced Plastic Cooling Towers (GB7190.2-1997)'. This series of cooling towers was jointly developed by the Fourth Design Research Institute and Tsinghua University, and the ultra-low noise cooling tower noise control system was completed in collaboration with the Beijing Labor Protection Research Institute.

设备说明

1. Wind tube

The RC4200 type rotary duct is made of flame-retardant fiberglass and formed through a molding process. It features a trapezoidal hollow reinforcement structure, with circumferential solid reinforcement ribs at both ends. The duct panels are connected using flange connections, and all fasteners are made of 0Cr18Ni9 stainless steel or Q235 Dacromet material. The duct surface is coated with a 0.5mm thick Ashland gel coat resin, which resists UV and photo-aging, and can withstand wind loads of up to 0.8kPa. The duct is equipped with a quick-opening maintenance door, and the handles, hinges, and bolts are all made of 0Cr18Ni9 stainless steel Q235 Dacromet material. The energy recovery value is at least 30%, and the duct has a service life of over 20 years.

2. Fan

The L4200 wind turbine, produced by the renowned domestic manufacturer Baiguan/Benofeng Wind Equipment Co., Ltd., features the latest blade technology. The blades are made of aluminum alloy and are manufactured using a special continuous integral molding process to ensure a continuous fiber structure at the leading edge, with a wear-resistant thin sheet covering the blade's leading edge. Both the blades and the hub have undergone static balance testing, achieving a static balance accuracy of at least G6.3 as specified in GB9239. The hub is secured with U-bolts, a high-strength aluminum alloy mounting base, and high-strength connecting bolts treated with Dacromet anti-corrosion technology using Japanese techniques. The gearbox is designed and manufactured according to the standards of the AmericanAGMA (American Gear Association), ASME (American Society of Mechanical Engineers), and CTI (American Cooling Technology Institute). The gearbox has a gear ratio greater than 2, with a transmission gear lifespan of 100,000 hours and a gear precision of 6. The gearbox housing is made from resin sand casting and has a HT200 grade. The gearbox uses a two-stage gear reduction transmission system, combining helical bevel gears and helical gears. It is equipped with a KR-939SB4 probe to monitor the XYZ three-dimensional vibration and oil temperature during the wind turbine's operation, and outputs a standard 4~20mA current signal to the main control room's DCS or PLC system, enabling remote automatic display, alarm, and shutdown. The steel base of the wind turbine is reinforced and treated with sandblasting and epoxy coal tar for corrosion protection. The base can be finely adjusted circumferentially and is equipped with anti-twist retaining iron, with the contact surface precision-machined.

3. Motor

Shanghai Jiamusi/Nanyang Electric Co., Ltd. produces YE4 explosion-proof motors, a company with a 50-year history as an old state-owned enterprise. Founded in 1969, the company specializes in motor production. The company produces outdoor motors with a capacity of 15KW, a voltage of 380V, a rated frequency of 50Hz, an IP55 protection rating, an F-class insulation rating, and continuous operation capability. The motor's steel base is designed with a reinforced structure and treated with sandblasting and epoxy coal tar for corrosion resistance. The motor base features horizontal and vertical fine adjustment holes, making debugging and maintenance very convenient.

4. The water collector is made of modified PVC material, specifically the BO160-45 type. The sheet contains rubber and plastic components, which are resistant to aging and do not deform. It does not soften when heated below 65℃ and has a low-temperature brittleness point of no more than-40℃. The sheet is designed with a composite sine wave pattern, ensuring no light transmission between sheets. This design ensures high water collection efficiency, minimal airflow resistance, high strength, and excellent flame retardancy. The water collector is installed on secondary beams, making it easy to install and maintain. After installation, it can achieve a drift loss rate of less than 0.001%, meeting international advanced standards. The physical and chemical properties comply with DL/T742-2001, the Technical Conditions for Plastic Components of Cooling Towers.

5. Water distribution system

A spray-type automatic pressure stabilizing pipe water distribution system is employed. The main water distribution pipe is made of DN350 carbon steel pipe, which is fully hot-dip galvanized. Inside the tower, the piping is made of UPVC material, known for its high mechanical strength, smooth inner walls, minimal water pressure loss, corrosion resistance, and light weight. The connecting bolts are made of 0Cr18Ni9 stainless steel/Q235 Dacromet material. Each distribution pipe is equipped with a pressure stabilizing box, featuring a pressure equalization design. Each tower is fitted with 260 sets of three-spray nozzles, which offer the best scattered water performance both domestically and internationally. The water distribution is uniform, with 90% of the nozzles having a deviation from the average flow rate of ±5%, and the remaining 10% having a deviation of ±10%. The volute nozzles, made from ABS material and injection molded, are suitable for a wide range of hydraulic loads (70%-130%). Anti-loosening measures should be implemented at the connection between the nozzles and the distribution pipe.

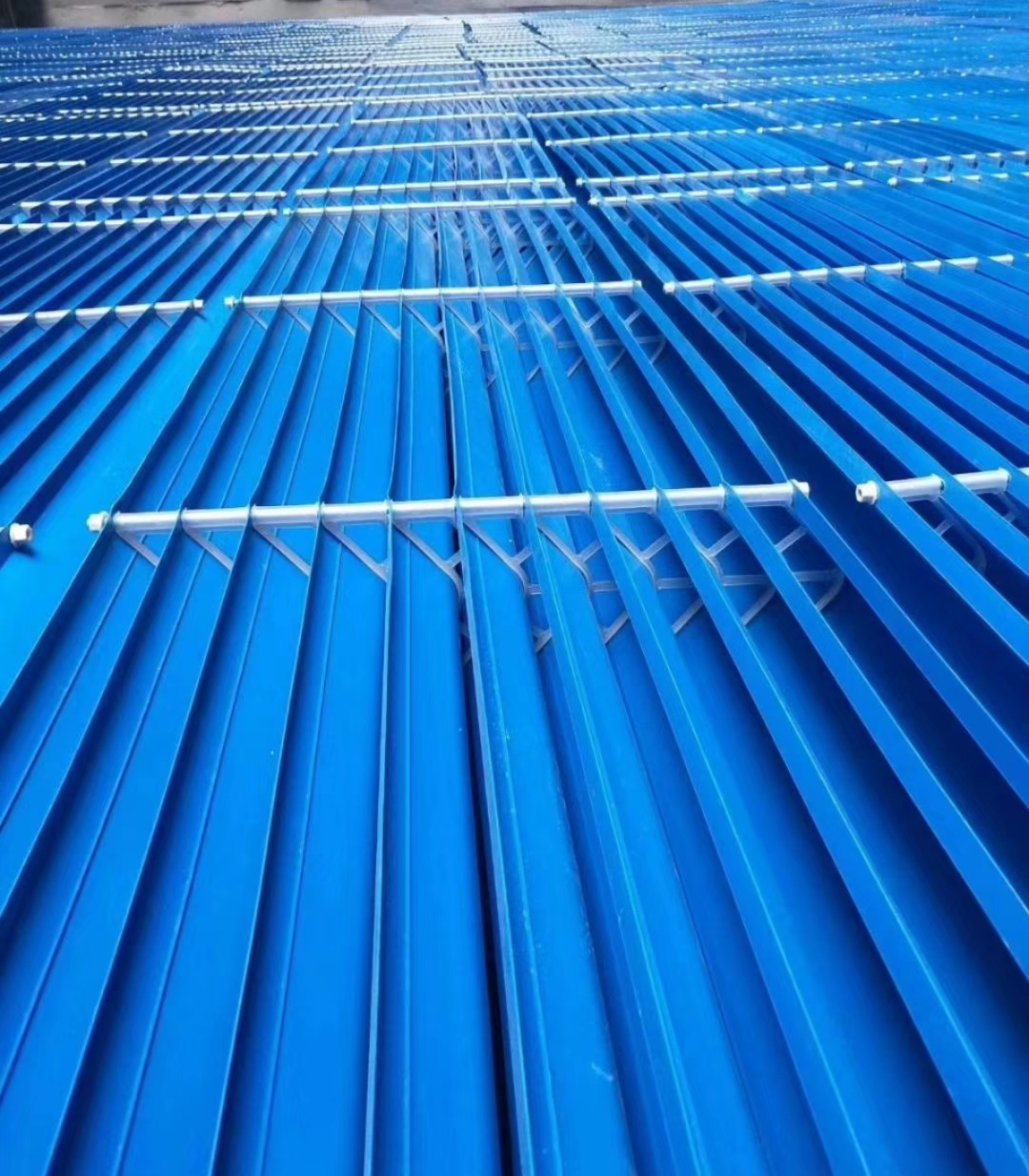

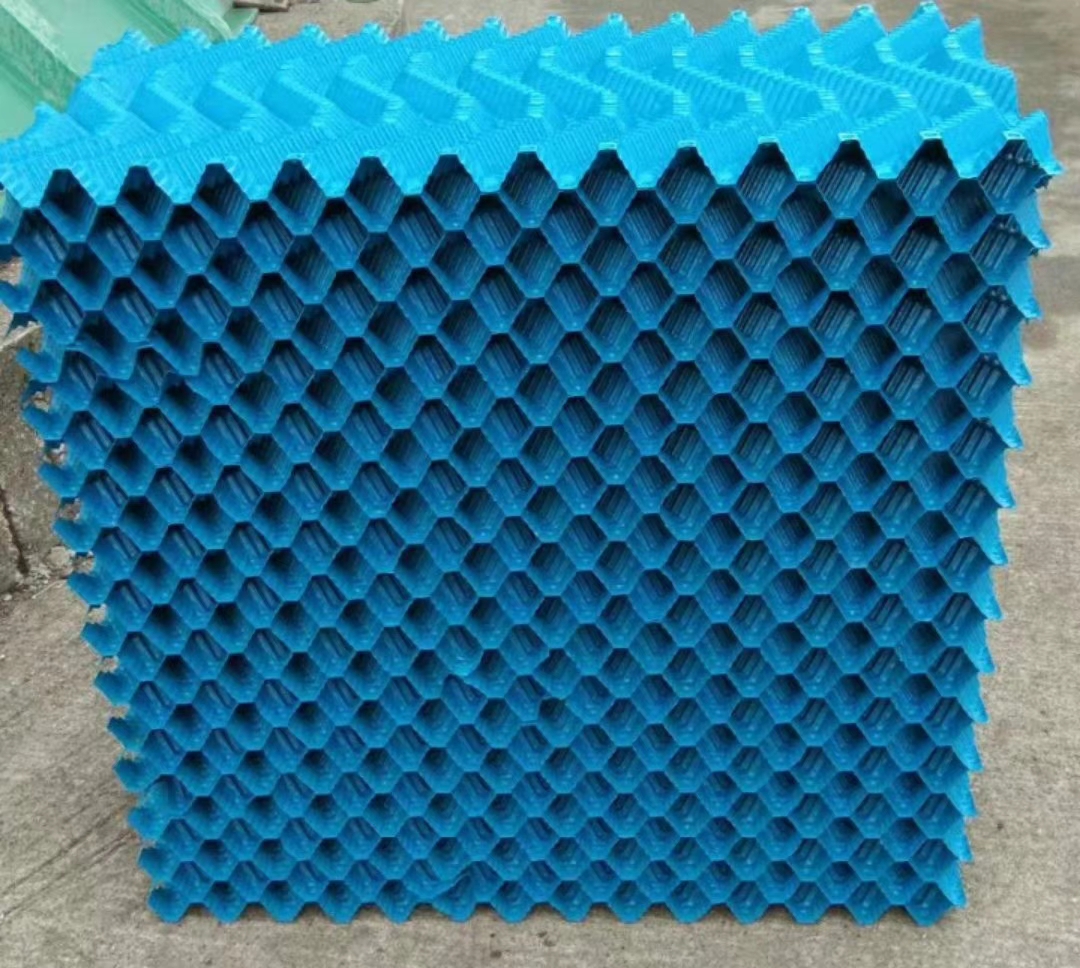

6. Water filling material

The grid-type PP filler is installed at a height of 1.50m, with a single piece measuring 810x810mm and a substrate thickness of 30/25mm. The thinnest part of the formed sheet is over 0.2mm thick. The filler has a density of less than 1.55g/cm3, a longitudinal shrinkage rate in boiling water of no more than 5%, an absorbency of no more than 0.15%, a tensile strength of 42Mpa at room temperature, a tensile strength of 38Mpa in the transverse direction, an oxygen index of 40 or higher, and a compressive strength of 360kgf/m2 or higher.

01

02

2. Spraying device

2.1, spray device model: three splash type.

2.2, spray device material: SS304 stainless steel.

2.3. The spraying device has the basic performance of uniform and small water droplets, no umbrella film and hollow phenomenon, large splash radius, strong adaptability to working head, and not easy to be blocked.

2.4. The spray device has the characteristics of simple and reasonable structure, convenient and reliable installation (bolt fastening installation process), overall stability and durability. Under normal operating conditions, it can withstand long-term pulsating water load, and the service life is not less than 10 years.

2.5, smooth surface, good plastication, regular shape, consistent color, no cracks, holes, bubbles, dents and obvious impurities.

2.6. The material of the spraying device and its accessories has good heat resistance and aging resistance.

7 Fiberglass part

The components of fiberglass include resin, fibers (such as fiber cloth and fiber felt), gel coat, and curing agent. It is manufactured using 190# surface adhesive and color pigments from Huari New Materials (a joint venture). The gel coat layer has a thickness of 0.3~0.5mm, a hardness greater than 47 on the Shore A scale, and a bending strength exceeding 250Mpa. The color pigments contain UVS light stabilizers, ensuring a uniform color tone that is resistant to aging and fading. A stringent quality management system ensures that the FRP parts achieve a mirror-like finish. Tests show that the surface glossiness ranges from 95 to 100 gloss units, with a flame retardant oxygen index of 32.2.

The outer side plates, top water collection basin, and air ducts of the cooling towers produced by our company are made from high-quality, high-density fiberglass formed through mechanical extrusion. Fiberglass pultrusion profiles serve both as a material and a structural component, offering great design flexibility. These profiles are manufactured using advanced hydraulic pultrusion equipment, where glass fiber yarn, fiber felt, polyester, and other reinforcing materials are heated and shaped in molds. This process eliminates all the drawbacks of hand-lay-up fiberglass, resulting in products with smooth surfaces on both sides, uniform curing, consistent color, excellent density, light weight, high strength, corrosion resistance, stable quality, and a long service life.

Weather resistance: the surface has a UV resistant co-extrusion layer, which can prevent resin fatigue and yellowing caused by ultraviolet light.

Impact resistance: due to the product structure contains crisscross glass fiber reinforced materials, which greatly improves the impact resistance of the product, and is not easy to break under the impact of gravel and hail.

Corrosion resistance: can resist all kinds of acid, alkali and other chemical substances corrosion.

Temperature resistance: FRP glass fiber is a thermosetting polymer materi

产品实拍: 客户使用现场案例

A:冶铜、冶钢领域使用

B:中频、淬火、真空炉领域使用

C:中央空调、辅助冷却、空压机系统、电力系统等领域使用

C:化工、特种设备、水源式冷却等领域使用

Jiangsu-Century China cold unit introduction

Jiangsu Shiji Huaneng Cold Industrial Development Co., Ltd. is specialized in the development, design, production, sales, consulting and service of cooling tower, air cooler and closed cooling tower. As an excellent manufacturing service provider of cooling tower, we have a group of excellent scientific research, development and manufacturing talents. In the development of high performance, high quality, high energy saving products at the same time, share our experience with customers, provide the most efficient energy saving plan, to reduce the use of cooling tower, improve the efficiency of cooling tower heat transfer, related engineering energy saving case has been put into operation, our aim: provide each customer with the most reasonable, professional energy saving scheme.

Jiangsu Century cold equipment involved in steel, petrochemical, pharmaceutical, automobile, casting, nuclear power plant, nuclear power plant, power plant, glass manufacturing, IT factory, food field, and air compressor, air conditioning system, induction electric furnace, casting equipment, glass melting furnace, injection molding machine, welding equipment coating equipment and other supporting equipment; we provide professional technical services and support to partners in various fields, to bring real added value, Century cold is your sincere partner in the field of heat exchange. Since its establishment, we have more than 500 customers, including the Chinese People's Liberation Army Nanhai fleet, Beijing Metal Research Institute, Wuhan Aviation Research Institute, Shanghai Qingning Environmental Design and Research Institute, Guoxuan Lithium, Jie Jiangsu Yifeng Group, Maoyuan Pharmaceutical Group and other large enterprises have chosen to cooperate with the century; we have won the trust and support of customers with excellent product quality and fast and keen after-sales service.

Jiangsu Shiji Hualeng Industrial Development Co., Ltd. has 76-100 employees, which is an independent legal person limited liability company. Among them, there are 14 experienced engineers and technicians with bachelor degree and a large number of employees with technical experience. Standardized plant area is 8000 ㎡. The company's internal quality control, in strict accordance with the ISO management system implementation standards, the production of cooling tower, air cooler, closed cooling tower equipment before the factory test, operation, testing, and then safe transportation to the customer project site.

华冷生产车间 简图介绍

Made in China cooling tower, m

Contact Us

Phone:+86 13961837633

Tel:+86 0510-81152329 +86 13961837633

Fax:+86 0510-81152329

E-mail:464788795@qq.com

Add:A31, No. 48-11 Renmin West Road, Hudai Town, Binhu District, Wuxi, Jiangsu Province, China