DB-HORSEPOWER BHL-H series closed crossflow cooling tower c

Product: Closed cross flow cooling towe

Tel:+86 13961837633

E-mal:464788795@qq.com

Add:A31, No. 48-11 Renmin West Road, Hudai Town, Binhu District, Wuxi, Jiangsu Province, China

E-mal:464788795@qq.com

Add:A31, No. 48-11 Renmin West Road, Hudai Town, Binhu District, Wuxi, Jiangsu Province, China

Made in china -

Jiangsu Century Hualeng Industrial Development Co., LTD

Focus on cooling tower: research and development, customization, production, service!

Manufacturer contact number: +86-13961837633 (China wechat account) Mr.Hu

Manufacturer contact email: 464788795@qq.com

Contact address: No.17, South Yingbin Road, Dongting Street, Xishan District, Wuxi City, Jiangsu Province

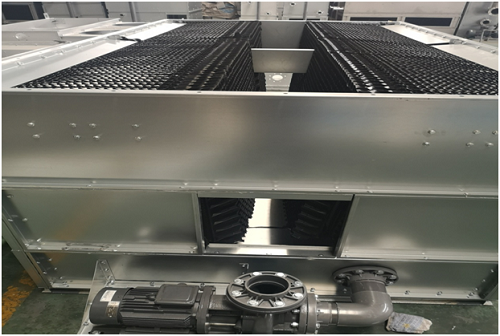

The BHL-H closed cross-flow cooling tower is essentially an evaporative cooling tower that combines the features of a cooler and a wet cooling tower. It is a horizontal evaporative cooling tower where the process fluid flows inside the tubes, while air flows outside, with no direct contact between them. The closed cooling tower represents a variation and development of traditional cooling towers. Water from the bottom sump is pumped and evenly sprayed over the outside of the tubes. Unlike conventional systems, the process fluid, whether hot water or refrigerant, does not come into contact with the air outside the tubes, making it a closed cooling tower. The spray water enhances heat and mass transfer. 2. The BHL-H closed cross-flow cooling tower is suitable for various cooling systems requiring high-quality circulating water, particularly in industries such as power, chemical, steel, food, and many others. Compared to air-cooled heat exchangers, evaporative cooling towers significantly enhance heat and mass transfer on the air side by utilizing the latent heat of evaporation from the water on the underside of the tubes, offering distinct advantages.

|

The outer box of BHL-N (H) series products is generally used as follows:

1: Korean Pohang magnesium aluminum zinc sheet

2: Pangang/Baosteel 304L stainless steel sheet metal

3: Baosteel aluminum-zinc coated sheet, it is one of the most corrosion-resistant sheets in today's world. Under the same corrosion conditions, the service life is 3-6 times that of ordinary galvanized sheet, and the service life is more than 20 years. It also has the advantages of strong heat resistance, high heat resistance and beautiful appearance

|

|

|

The BHL-N (H) ventilation system uses direct supply from the top three fan manufacturers in the domestic industry. It features aluminum alloy axial fans specifically designed for the Qianchuan and Heme cooling towers, with a forward-curved blade design, streamlined inlet ducts, low air resistance, high airflow, low noise, excellent performance, and high efficiency. The system is beltless, reducing transmission components, and uses fully enclosed self-cooling, low-noise motors for the cooling towers, or Siemens and Jiamusi motors, which are compact, lightweight, have excellent start-up performance, reliable operation, and are durable. | |

|

Stainless steel table cooler (cooling coil)

A. The cooling coil shall be made of φ19mm, δ=1 mm SS304L stainless steel U-tube, and the water flow direction of each heat exchange tube shall form a reverse flow of air and water with the direction of air flow outside the tube.

B. The support frame of the cooling coil shall be made of SS304L stainless steel angle iron welded, and its processing and welding process shall meet the requirements of relevant national standards for metal processing and welding. The surface cleaning and coating of the support frame shall be the same as that of the cooling tower frame.

C. The connection between the inlet and outlet water pipes of the cooling coil shall be flanged.

D. Each group of heat exchange tubes should be pre-inspected and pressure tested before assembly. After the cooling coil is assembled, a 1.6Mpa pressure test should be carried out in water, and a 1.2Mpa water pressure holding test should be carried out after the whole tower is formed to ensure no leakage.

|

|

|

T2 deoxy copper surface cooler (cooling coil)

A. The cooling coil should be made of T2 deoxidized purple copper U-tube with φ19mm and δ=1mm. The water flow direction of each heat exchange tube group should form the reverse flow of air and water outside the tube.

B. The support frame of the cooling coil shall be made of SS304L stainless steel angle iron welded, and its processing and welding process shall meet the requirements of relevant national standards for metal processing and welding. The surface cleaning and coating of the support frame shall be the same as that of the cooling tower frame.

C. The connection between the inlet and outlet water pipes of the cooling coil shall be flanged.

D. Each group of heat exchange tubes should be pre-inspected and pressure tested before assembly. After the cooling coil is assembled, a 1.6Mpa pressure test should be carried out in water, and a 1.2Mpa water pressure holding test should be carried out after the whole tower is formed to ensure no leakage

|

|

|

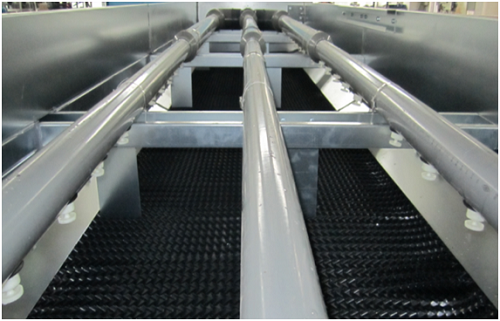

The water spray packing is made of flame-retardant modified P.V.C plastic S-wave film. The packing has a spacing of 30mm, a flame retardant oxygen index greater than 40, and the base sheet thickness is no less than 0.40mm±0.05mm. It features excellent thermal performance, low ventilation resistance, a high cooling heat transfer area and efficiency, and good flame retardancy, ensuring sufficient heat exchange time for water and air within the packing.

The overall assembly block of the water sprinkling packing has good strength. The packing is assembled into blocks by threading, and the packing rod is made of PVC plastic material.

|

|

|

distributed system

Whether the water distribution of the cooling tower is uniform or not is the key to the heat exchange between water and gas. The heat exchange effect accounts for about 20% of the cold effect of the whole tower. The quality of the water distribution performance will directly affect the uniformity of air distribution and the ability of the packing to play the cooling role.

|

|

|

All fasteners in the closed cooling towers produced by our company are galvanized. The corrosion resistance and rigidity of these bolts far surpass those of ordinary bolts. This ensures the long-term stable operation of the closed cooling towers and provides reliable support for users who frequently need to move and install products during mobile construction. | |

|

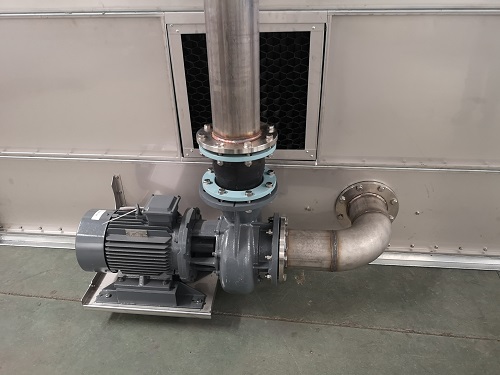

Spray pump (see table for specific parameters)

A, small body small installation volume, light weight, straight pipe, can be easily installed in the middle of the pipeline

B. Silent design The motor adopts low noise fully enclosed outdoor motor with anti-splash and dustproof, which can be installed both indoors and outdoors

C. Prevent water leakage Due to the use of mechanical seal, it prevents water leakage, and is durable and easy to maintain

D. Rust prevention treatment The LP pump is coated with epoxy resin, and the LPP pump adopts cast iron pump body, so it has a great rust prevention effect

e. The pump body of LP and LPP is constructed with precision casting, which is strong and has a long service life, so it can be used as a circulating pump.

|

|

|

Auxiliary equipment (water tank)

The water tank is made of 304 stainless steel. The components are hot-dip galvanized, and the circulation pump is a high-quality domestic model, also available as Hualei Pump Industry pumps under the Century Hualeng brand. It features an internal liquid level alarm to effectively control energy consumption and ensure water supply during normal operation.

|

|

|

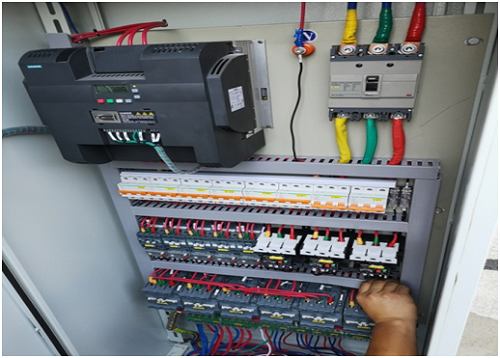

The electrical control box is made of a baked enamel steel body. Equipped with Zhengtai or Schneider electrical components, it is waterproof, corrosion-resistant, and dustproof. It features a Siemens PLC-based microcomputer control system with both manual and automatic modes. It continuously monitors water temperature parameters and equipment operation, effectively ensuring workshop productivity | |

产品实拍: 客户使用现场案例

A:冶铜、冶钢领域使用

B:中频、淬火、真空炉领域使用

C:中央空调、辅助冷却、空压机系统、电力系统等领域使用

C:化工、特种设备、水源式冷却等领域使用

Jiangsu-Century China cold unit introduction

Jiangsu Shiji Huaneng Cold Industrial Development Co., Ltd. is specialized in the development, design, production, sales, consulting and service of cooling tower, air cooler and closed cooling tower. As an excellent manufacturing service provider of cooling tower, we have a group of excellent scientific research, development and manufacturing talents. In the development of high performance, high quality, high energy saving products at the same time, share our experience with customers, provide the most efficient energy saving plan, to reduce the use of cooling tower, improve the efficiency of cooling tower heat transfer, related engineering energy saving case has been put into operation, our aim: provide each customer with the most reasonable, professional energy saving scheme.

Jiangsu Century cold equipment involved in steel, petrochemical, pharmaceutical, automobile, casting, nuclear power plant, nuclear power plant, power plant, glass manufacturing, IT factory, food field, and air compressor, air conditioning system, induction electric furnace, casting equipment, glass melting furnace, injection molding machine, welding equipment coating equipment and other supporting equipment; we provide professional technical services and support to partners in various fields, to bring real added value, Century cold is your sincere partner in the field of heat exchange. Since its establishment, we have more than 500 customers, including the Chinese People's Liberation Army Nanhai fleet, Beijing Metal Research Institute, Wuhan Aviation Research Institute, Shanghai Qingning Environmental Design and Research Institute, Guoxuan Lithium, Jie Jiangsu Yifeng Group, Maoyuan Pharmaceutical Group and other large enterprises have chosen to cooperate with the century; we have won the trust and support of customers with excellent product quality and fast and keen after-sales service.

Jiangsu Shiji Hualeng Industrial Development Co., Ltd. has 76-100 employees, which is an independent legal person limited liability company. Among them, there are 14 experienced engineers and technicians with bachelor degree and a large number of employees with technical experience. Standardized plant area is 8000 ㎡. The company's internal quality control, in strict accordance with the ISO management system implementation standards, the production of cooling tower, air cooler, closed cooling tower equipment before the factory test, operation, testing, and then safe transportation to the customer project site.

Made in China cooling tower m

Hot Product

Contact Us

Phone:+86 13961837633

Tel:+86 0510-81152329 +86 13961837633

Fax:+86 0510-81152329

E-mail:464788795@qq.com

Add:A31, No. 48-11 Renmin West Road, Hudai Town, Binhu District, Wuxi, Jiangsu Province, China