DB-HORSEPOWER Fiberglass cooling tower

Product: Square cross flow cooling towe

Tel:+86 13961837633

E-mal:464788795@qq.com

Add:A31, No. 48-11 Renmin West Road, Hudai Town, Binhu District, Wuxi, Jiangsu Province, China

E-mal:464788795@qq.com

Add:A31, No. 48-11 Renmin West Road, Hudai Town, Binhu District, Wuxi, Jiangsu Province, China

Made in china -

Jiangsu Century Hualeng Industrial Development Co., LTD

Focus on cooling tower: research and development, customization, production, service!

Manufacturer contact number: +86-13961837633 (China wechat account) Mr.Hu

Manufacturer contact email: 464788795@qq.com

Contact address: No.17, South Yingbin Road, Dongting Street, Xishan District, Wuxi City, Jiangsu Province

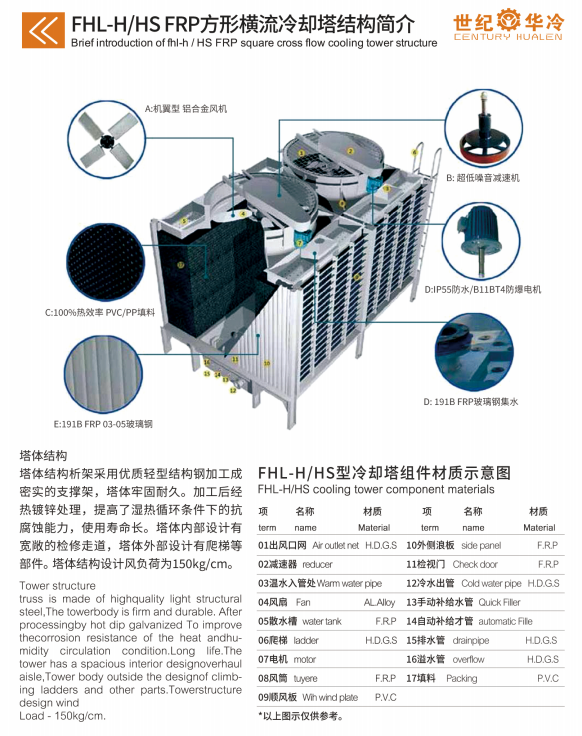

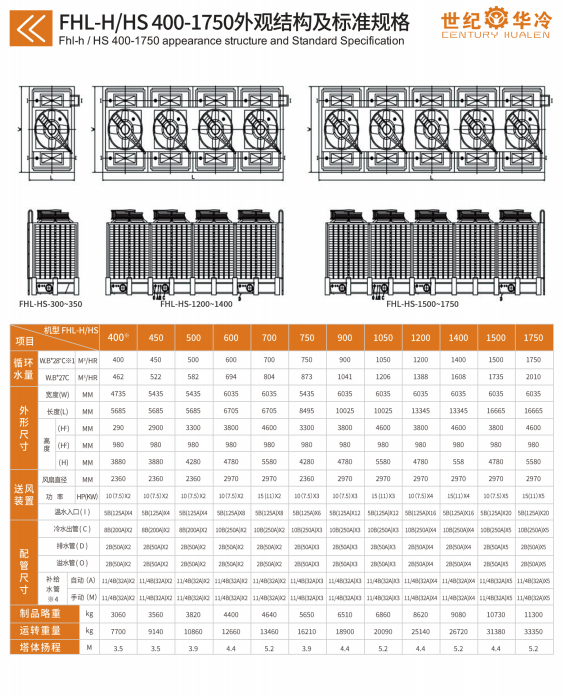

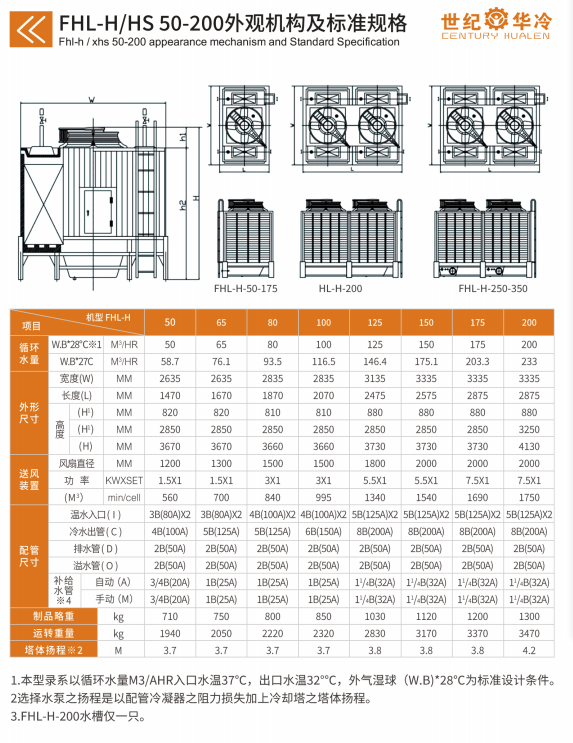

Overview of FHL-H FRP open cooling tower series

FRP open cooling tower is a mature and reliable cooling equipment formed by our company after years of design, manufacturing and continuous improvement and perfection, so that the product quality and technical performance are always in the leading position in the industry.

Glass fiber reinforced open tower is widely used in industrial heat fluid, metallurgy (blast furnace, continuous casting mold), medium and high frequency induction heater, chemical (heat exchanger), power equipment, casting, forging, quenching liquid, manufacturing, food, air compressor, central air conditioning and many industrial departments as a universal cooling equipment.

The basic principle of cooling of glass fiber reinforced plastic open cooling tower

Fiberglass open cooling tower is a device that uses the contact (direct or indirect) between air and water and sprays packing to cool and dissipate heat, and takes away the heat through fans to cool water, with water as the circulating cooling medium.

The glass fiber reinforced plastic open cooling tower is mainly composed of six parts: spray packing system, spray water circulation system, collector system, control system, shell and frame and fan.

Under the drive of the main circulation pump, soft water circulates in an open system within the cooling tower's spray packing. Heat is transferred to the surface of the packing, and the spray water falls vertically from the top of the tower. The water collector system sprinkles over the outer surface of the packing, forming a uniform water film. After heating, this water forms saturated hot steam. Fresh air enters the tower through the intake at the bottom, with the airflow and water flow being perpendicular to each other. During the circulation, the spray water is sprayed onto the surface of the packing for heat exchange, and the heat is discharged into the atmosphere by the fan. To reduce the temperature of the circulating water, two types of heat exchange occur: the heat transfer between the cold air and the cooling medium, and the heat absorption through the evaporation of the spray water, which absorbs heat and lowers the temperature of the working fluid. The saturated hot steam is then discharged upward by the fan.

2.Design process of FRP square cross-flow cooling tower

Ø Outer shell: 191B epoxy resin (FRP) molded sheet

Ø Maintenance: Century Hualeng has a unique design that allows access to the maintenance channel inside the equipment.

Ø Air inlet grille: Century Hualeng's unique high efficiency air inlet grille (PVC material) for separate cooling of spray water and cooler.

Ø Fan: It adopts a three-proof motor with IP55 protection class and F insulation class.

Ø Wind cylinder: Inductive FRP molded wind cylinder is used to reduce air backflow and leakage.

Ø Protective cover: corrugated carbon steel integral hot-dip galvanized protective cover to prevent debris from entering the fan.

Ø Sprinkler head: a new type of flower nozzle, with fine water droplets, uniform water spraying and large water distribution area.

Ø Collector: FRP closed uniform water basin design

Ø Water collection tank: large water collection, wide area, good heat dissipation, fully meet the technical requirements of sprinkler water.

Ø Float ball valve: 304 stainless steel to ensure the water tank storage capacity.

Ø Pre-cooling filler: the American horsepower type heat dissipation filler is used. The evaporation heat transfer of water reduces the temperature of cooling water, and the water blocking plate in front effectively reduces the loss of floating water.

Ø Brand of electric control box: Chint/Schneider.

Ø Remote control: start and stop buttons for water pump and fan are provided.

Ø System control: the system operates a fault alarm system.

Ø Indicators: power on indicator, operation, shutdown and fault display lights.

设备选材说明

|

FHL-H series of square cross-flow cooling tower is a mature and reliable cooling equipment formed by our company after years of design, manufacturing, continuous improvement and perfection. The product quality and technical performance are always in the leading position in the industry. |

|

The base of the fan is reinforced with sheet metal material produced by carbon steel/Baosteel and other manufacturers. The base of the fan can be adjusted slightly in circumference, and there is a torsion-proof iron. The contact surface is finely processed, and the motor base has horizontal and vertical fine adjustment holes to ensure that debugging and maintenance are very convenient. Sandblasting is used for rust removal, and epoxy coal tar is used for anti-corrosion. |

|

High thermal performance and not easy to block PVC material is used, ton Han horsepower filler is used, sheet physical and chemical properties meet the requirements of DL/T742-2001 "Technical conditions for plastic parts of cooling tower". |

|

Wing type, high quality cooling tower dedicated axial flow aluminum alloy fan, 0Cr18Ni9 stainless steel transmission shaft. |

|

Molded FRP duct

|

|

The internal structure adopts simple and practical century, with large space. The water storage space is large, more convenient for maintenance and maintenance, etc., |

|

The spray system uses ABS/PP material for low-pressure nozzles, which feature a large nozzle diameter and are designed to prevent clogging. The water is sprayed evenly without any hollowing, and the mist-like droplets do not affect the uniformity of air distribution. It has a wide range of hydraulic load adaptability and features a self-drain function. The connection between the nozzles and the distribution pipes is made using a threaded connection, ensuring the system operates safely over the long term. |

|

DZ85 type, carbon steel material (overall hot galvanizing) reinforced base, the fan base can be adjusted in circumference, and has anti-twist iron, contact surface precision machining, motor base set with horizontal and vertical fine adjustment holes, to ensure that debugging and maintenance is very convenient, sandblasting rust removal, epoxy coal tar corrosion protection. |

Product shooting: customer use case

A: Used in the field of copper and steel smelting

B: Used in medium frequency, quenching and vacuum furnace fields

C: Used in central air conditioning, auxiliary cooling, air compressor system, power system and other fields

D: Used in chemical industry, special equipment, water source cooling and other fields

C:化工、特种设备、水源式冷却等领域使用

Jiangsu-Century China cold unit introduction

Jiangsu Shiji Huaneng Cold Industrial Development Co., Ltd. is specialized in the development, design, production, sales, consulting and service of cooling tower, air cooler and closed cooling tower. As an excellent manufacturing service provider of cooling tower, we have a group of excellent scientific research, development and manufacturing talents. In the development of high performance, high quality, high energy saving products at the same time, share our experience with customers, provide the most efficient energy saving plan, to reduce the use of cooling tower, improve the efficiency of cooling tower heat transfer, related engineering energy saving case has been put into operation, our aim: provide each customer with the most reasonable, professional energy saving scheme.

Jiangsu Century cold equipment involved in steel, petrochemical, pharmaceutical, automobile, casting, nuclear power plant, nuclear power plant, power plant, glass manufacturing, IT factory, food field, and air compressor, air conditioning system, induction electric furnace, casting equipment, glass melting furnace, injection molding machine, welding equipment coating equipment and other supporting equipment; we provide professional technical services and support to partners in various fields, to bring real added value, Century cold is your sincere partner in the field of heat exchange. Since its establishment, we have more than 500 customers, including the Chinese People's Liberation Army Nanhai fleet, Beijing Metal Research Institute, Wuhan Aviation Research Institute, Shanghai Qingning Environmental Design and Research Institute, Guoxuan Lithium, Jie Jiangsu Yifeng Group, Maoyuan Pharmaceutical Group and other large enterprises have chosen to cooperate with the century; we have won the trust and support of customers with excellent product quality and fast and keen after-sales service.

Jiangsu Shiji Hualeng Industrial Development Co., Ltd. has 76-100 employees, which is an independent legal person limited liability company. Among them, there are 14 experienced engineers and technicians with bachelor degree and a large number of employees with technical experience. Standardized plant area is 8000 ㎡. The company's internal quality control, in strict accordance with the ISO management system implementation standards, the production of cooling tower, air cooler, closed cooling tower equipment before the factory test, operation, testing, and then safe transportation to the customer project site.

Made in China cooling tower, m

Contact Us

Phone:+86 13961837633

Tel:+86 0510-81152329 +86 13961837633

Fax:+86 0510-81152329

E-mail:464788795@qq.com

Add:A31, No. 48-11 Renmin West Road, Hudai Town, Binhu District, Wuxi, Jiangsu Province, China